When we threw down the gauntlet on ourselves on 24 Nov 2018, the challenge was to stop laying about and put in extra shifts at the coalface to get the final occupancy permit on our house five month later. D-day was in the calendar: 24 April 2019.

So did we do it? Kind of, mostly, yes. But it was a rocky ride.

Yes, that’s our powerline on the ground with a tree on top

With winter came a few spanners in the works. The first being a nine-day power outage over Christmas when a massive mid-day windstorm left three quarters of a million people on Vancouver Island without Netflix and toppled a massive tree on our power line. For us it was a most Victorian Christmas.

However, by far the hardest blow was the passing of my dad, Wilf West, following a stroke in January. A lot of what I know about building rests on a deep foundation attributable to my dad. Not so much the specific nuts and bolts but rather the steeped-in-your-blood deep memory that anything can be built with enough thought. Being a book guy [though admittedly I considered becoming a machinist], I’d never built a house before, but having grown up with free run of Wilf’s workshop and living in a construction site when my dad decided to double the size of our house in the 80s, it seemed natural that I should later build my own house.

Wilf building the chimney on our Calgary house c. 1976

From day one my dad took a huge interest in our project and over several years he and my mum pitched in with some heavy lifting whenever they visited. He taught me to survey and helped me map our house site, build our power shed, and raise the first house wall. He and my mum also precisely taped our subfloor vapour barrier, kneeling on rock for three straight days, while I cleverly absconded to New Mexico for a work trip. My dad also helped lay tonnes of cob flooring, plaster walls, prepare for roof insulating, and he sanded some of our custom fir windowsill slabs. I’m devastated that he never got to see the house completed, but I can say without question that our house stands because of his life long role modelling.

***

By mid-spring we were in a mad dash to the finish line ticking off dozens of jobs including final exterior lime plastering, exterior gable siding, tongue and groove soffits, exterior window casings, final upstairs earthen floors, storm drain, stair railings, final electrical work, commissioning the heat pump, and taking down scaffolding.

The final house inspection by the Nanaimo Regional District building inspector was on May 3, however it took a couple of more weeks to secure the occupancy permit as we had to replace the glazing in a stair bottom window with tempered glass so the inspector could sleep at night.

‘The Sharn’

With the occupancy permit firmly in hand I immediately put down tools on the house and started on a structure in our garden area that we refer to as ‘The Sharn’ – more than a shed and less than a barn. It’s a multipurpose structure about 44’ long and 18’ wide [13.5 X 8.8m]. The south facing roof is sloped at 29 degrees, which at our latitude is the optimal angle for summertime solar photovoltaic generation so the roof doubles as a rack for our 16 panel, 4kW grid-tied PV system. One end is a massive glorified wheelbarrow carpark, and will eventually have a vegetable wash station, tool racks and a place for a hammock between the posts. The other end is a fully insulated, heated, and rodent proof storage building for tools, chicken feed, several large chest freezers for berries, fruit and veg, plus shelves for preserved foods and wine. The PV system went live on July 16 and to date has generated about 1000 kW hours, some of which has been used on site and some exported to the BC Hydro grid.

Berms for fruit and nut trees in mid-plant

Earlier in the spring we also took some time to build substantial earth berms and planted out about two dozen apple, pear, hazelnut, and sweet chestnut trees. These are the first of dozens, perhaps hundreds, of fruit and nut trees that will form the backbone of a perennial food system designed to provide resiliency and food security as climate change really starts to bite. Despite teaching full time, Karen still managed to put in about 1000 feet [300 m] of garden beds and our 99-hen heritage flock produced roughly 10,000 eggs.

Most importantly though, despite the marathon dawn till dusk hammer swinging and mud slinging, we still managed to party. In mid-in August, almost exactly six years to the day we bought land while living in a van and shitting in the woods, we finally took time out to host a housewarming party to thank the legions of people who pitched in one way or another to build our house and budding resilient microfarm. Ultimately this project is as much about community as it is about low-carbon, natural building, energy efficiency, and food growing. When we washed up on shores of this rock we knew not a single person and six years later we have a community to thank for the rich, abundant place we call home. Please take a moment to have a look at the Honour Roll down below the photos – you may well be on it!

With electrons now zipping though the PV panels, I threw up the the largest woodshed on Gabriola – 36’ X 10’ [11 x 3 m] – and a two-bay post and beam structure for manure and compost in the garden. In November, I’ll be erecting a rodent proof feed storage building so we can order organic chicken feed in bulk from the BC mainland as there’s currently no bulk organic feed supplier on Vancouver Island.

Despite best intentions, the house still has a bit of cosmetic work remaining, including interior trim work plus the library shelves to house the multiple volumes of Das Kapital, dozens of rare Earthscan collectibles, the entire Sustainable Building Essentials series, my brewing books, and a dog-eared copy of The Rum Diary.

Baseboards or not, the beds are comfy, the shower is hot, and the toilets flush. So we are open to visitors so let us know when you are coming. We have 50 bottles of blackberry wine stashed that need drinking and we can have eggs for breakfast. Lots, and lots of eggs. And this time round I won’t make you lift anything heavy.

Cedar siding over a rainscreen gap and lime-clay wall

It always ends in the dark

East gable sided and lime plaster on the south side

Pine tar from Sweden tinted with oxide from the ancient Falun mine

Lime plaster sneaking around to the west side

Be still my beating builder’s heart

The north side took a bit longer

Dodgy fresh egg market trader hanging about our farmstand

Installing the stair top fir newel posts so they never move no matter how many 8 year old climbers pile on

Laying the upstairs earthen sub-floor

And the final earthen floor

Finishing the stair railings. Floor slabs on the right will be the base of the library bookshelves

Linseed oil on the library T&G hemlock ceiling

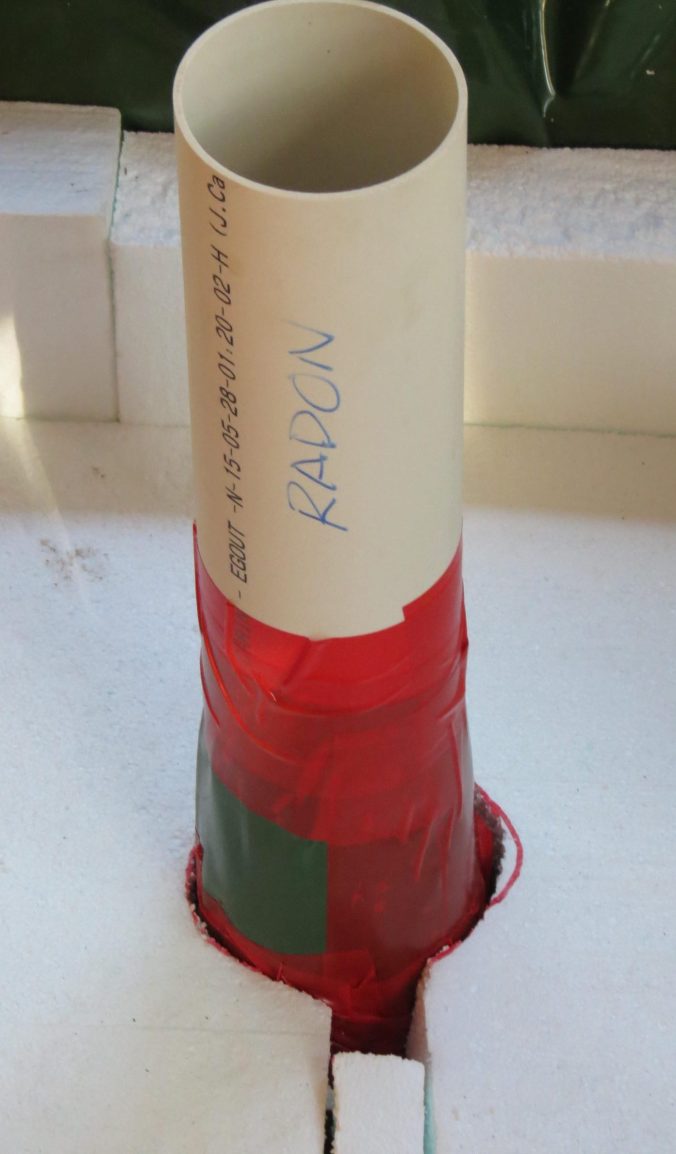

Installing the storm drain for the roof downspouts

The Glass Guy [his real name] installing the tempered glass into the stair bottom window to satisfy the inspector, who likes to read the BC Building Code before bed

The garden came along quite nicely

Foundation piers for ‘The Sharn’

The Sharn fir post and beam

Sharn clerestory roof design with 29 degree south slope

Rodent proof wire mesh under the floor

4kW PV system on the roof and closed up east end to house my country wine

The post and beam woodshed. It’ll hold 18 cords / 65 cubic metres of firewood. Enough to keep us going until into the 2030s

The compost shed with its first steaming pile

‘The Sharn,’ PV array, and the house in the background

Mia hanging with her mate Chocolate Brown

The House Build Honour Roll

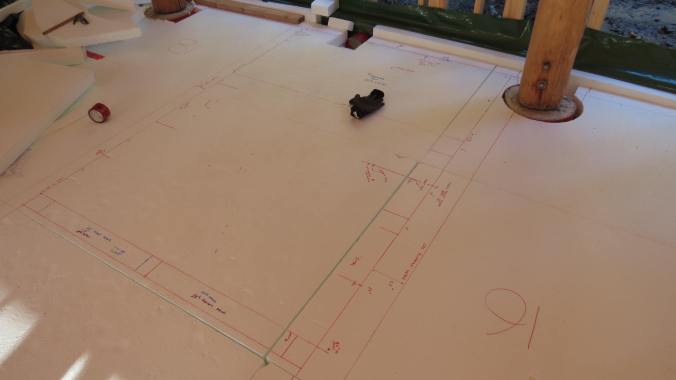

Drawings and Engineering

Cindy McCaugherty – Raincoast Homes – putting our outlandish ideas into house plans

Kris Dick – Building Alternatives – engineering

Septic

Ian Ralston – Traxx Developments – septic design and commissioning

Howard Hells – septic headworks assembly

Trades

Electrical – Ted Ramey, Ramey Systems including apprentices Charlie and Rob, Jess, and Harvey

Plumbing – Scotty’s Plumbing

Excavating and site clearing – Thor Simrose

Roof – Stevo’s Roofing

Steve Finney – upstairs shower construction and upstairs bathroom floor tiling

Materials

Arbutus Building Supply – the whole crew

Hi-tec – roof trusses

Longhouse Cedar – fir and hemlock T&G

Finish clay – Vancouver Island Potters’ Supply

The Heavy Lifters – Special Thanks

These people went above and beyond and for that we will always be grateful.

John Switzer – for endless help over the years including but not limited to form construction, concrete pour, excavating, lifting and installation of all the heavy timbers, truss lifting, wall plastering, earthen floor laying, insulation moving, window moving, lending me his excavator for all manner of work including building the septic field, ideas, advice, tools, machines plus food growing training for Karen, chicken brooding, and much, much more.

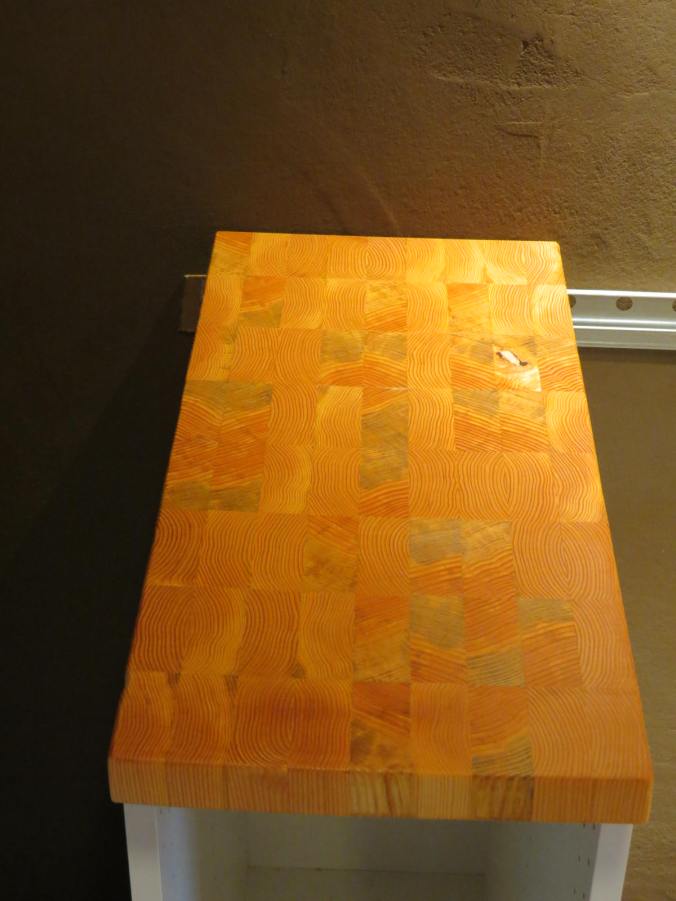

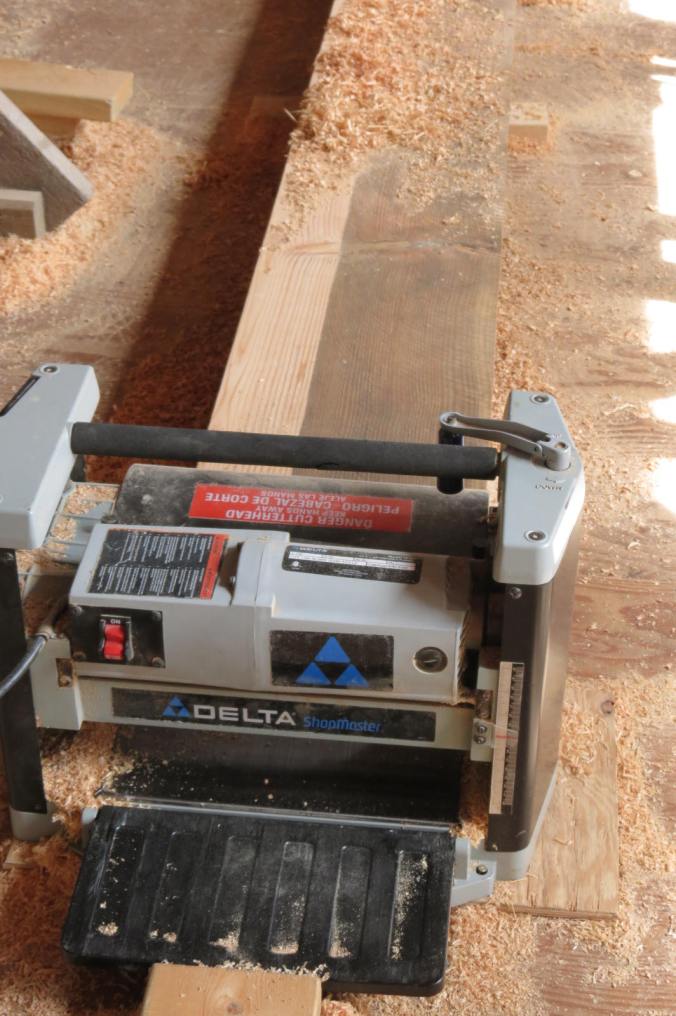

Wilf West – inspiration to build, early tool training, precision, power shed construction, wall construction, sub-floor vapour barrier, earthen floors, wall plastering, window sill slab sanding.

Dorothy West – precision, window and door air sealing, sub-floor vapour barrier, earthen floors, wall plastering, childcare, feeding the concrete pour team.

Mia MacDonald-West – earthen floor, handing me screws, gluing insulation fabric to studs, being an amazing construction site kid and spending countless days playing in a construction site winter and summer.

Kevan Heughan – masses and masses of wall plastering, days and days of septic field trench digging, and miles of lath ripping – you are a machine.

Chris Sauer – for taking time out of his own house build for the truly epic 112 sheet plywood roof installation, ripping lath [and his finger].

The Many Other Helpers

Ben Abrams – heat pump refrigeration lines

Tom Archdekin – tree felling

Gord Baird – advice on heating system,

Penelope Bahr – idea, tools and equipment, inspiration

Elisha Bandel – tools, surface plane, excavator loan, advice

Nadine Bariteau – bathtub moving, wall plastering, earthen countertop repair, gable staining

Blaine Borley – timber drilling jib bushing fabrication

Chris Boulsby and Sustainable Gabriola, heat pump supply

Darcy Boulton – wall plastering, tools

Rose Boulton – lots of childcare

Fin Bradbrooke – septic field trenching

Shay Brazier – laying out the string lines for the foundation, advice on PV system and heating system options

Shawn Colbourne – door pick-up

Liam Colbourne – septic field trenching

Sukita Reay Crimmel – the Queen of Earthen Floors – floor construction advice in person and in her book Earthen Floors

Bob Crozier, Knotty Pines – heat pump commissioning

Alex Dewar – concrete pour, advice, materials

Fabrication Unlimited – flitch plate fabrication

Peter Forde – east gable wall top plate layout and installation

Jen Feigin – plastering advice

Becky Furnell – advice, ideas, materials

Darren Gray – beam sanding and installation

Polly Heath – advice and inspiration

James Henderson – plastering advice including clay-lime recipe

Trevor Hendricks – brokering our land purchase, form inspection and suggestions, window unloading,

Mike Henry – plastering advice and earthen floor oil mix

Genevieve Hicks – concrete pour, wall plastering

Ben Jenkins – stair tread planning (with Ash), stair landing installation, window installation, moving heavy stuff

Kathleen Kane – ideas and advice, tools, material supply and pick-up, wall plastering

Linnet Kartar – house siting

Helen Keevy – wall plastering

Yarrow Koontz – house siting, wall plastering

Trish Leather – organizing our house rental and lots of childcare

Mark and Kathy Leather – house rental

Corey Mabbutt – tree felling

Cherie MacDonald – erection of ‘a wall’ and childcare

Tammy MacDonald– facia board staining and installation

Jen MacFarlane – truss lifting, bathtub moving, wall plastering, earthen countertop repair, gable staining

Chris Magwood – plastering advice, general advice, finish plaster coat recipe, inspiration for the roundwood beams

Bill at Marine Fabrication and Machine – post tie down and connectors fabrication

Simon Matijasevic – lath pick-up, advice and ideas

Steve McAdam – timber grading

Bill McCaugherty – advice

Michael Mehta and Gab Energy – PV system organizing

The Mud Girls – inspiration and training with cob

Ash – stair tread planing

Isaac – septic field trenching

Max Oleksyn – gable belly boards installation and window lath

Mary-lou Pacione – erection of ‘a wall’

Pat Prosser – gable wall stud cutting and construction

Andrew Prosser – foundation forms and concrete pour

Jacob Deva Racusin – plastering advice, including clay-lime recipe

Leo Reeves – septic field trenching

Melody Scroggins and Darren – door hardware and bathtub pick-up

Jo Spivak – truss lifting

Krista Spivak – truss lifting

Nate Seigers – timber milling

Drew Staniland – house siting, concrete pour, wall plastering, tools

James Thomson – floor construction advice in his book Earthen Floors

Thomas Uhlig – lots of childcare

Ed West – dormer wall construction

Steve Wilford – PV system installation and garden shed wiring with apprentice Stewart