Six months ago, the Douglas fir came crashing down. Today we started putting it back up again. The cultural historian in me reflecting on the unfolding story of the fall and redemption. The builder in me sharpening my chisels and wondering how to move a 120 kg post.

After the epic January tree felling, Karen put in a few hundred hours getting ripped by hand peeling the logs with a heavy bladed ‘spud’.

Then last week we surveyed the elevations of the tops of all our foundation piers and I calculated the required post heights for the round wood beams and 6×12 joists to be as level as possible at the necessary final elevation. There’s only a variation of 12mm across the entire foundation system, which I’m pretty happy about considering it was all laid out on a jumbled mass of broken rock with a builder’s level, string lines put up with the help of a sick Kiwi, and a plumb bob.

Resting regally on saw bucks I built last autumn, we deployed an arsenal of scrub pads, air tools and elbow grease to clean up the first post. Sporting a fresh chain on the venerable West German-made Stihl chainsaw, I cut the first post to length and then with a decided lack of grace, sliced a slot in the bottom end to slide over the 3/8 inch steel blade embedded in one of the concrete piers.

Oh it looked good, and it looked bleeding heavy.

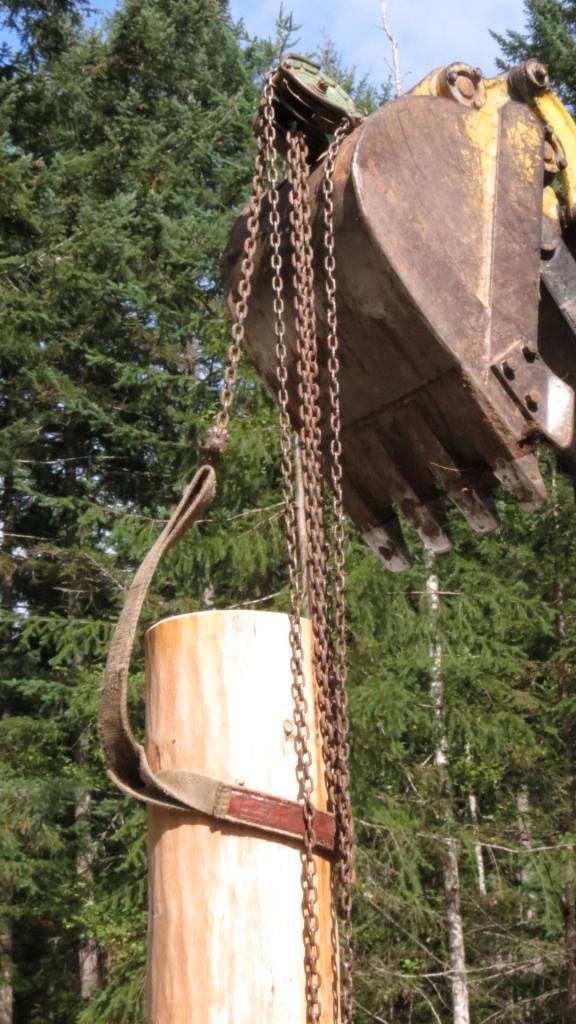

As well as teaching Karen how to grow organic food at scale, producing probably the best tomatoes on Gabriola and being one of the most generous people imaginable, our radical farmer neighbour John also happens to have a small excavator. When he offered to lend it to us – a giddy man driving an excavator onto your land should never be refused – I released the slaves from my Iron Age building project and violà, the first post was erected.

Once in situ I plumbed it and bored two holes through the post and blade to take hefty ¾ inch bolts that arrive next week.

And there it was in all its golden glory, The First Post. One up and 21 to go.

To say we are chuffed is an understatement. This is it!